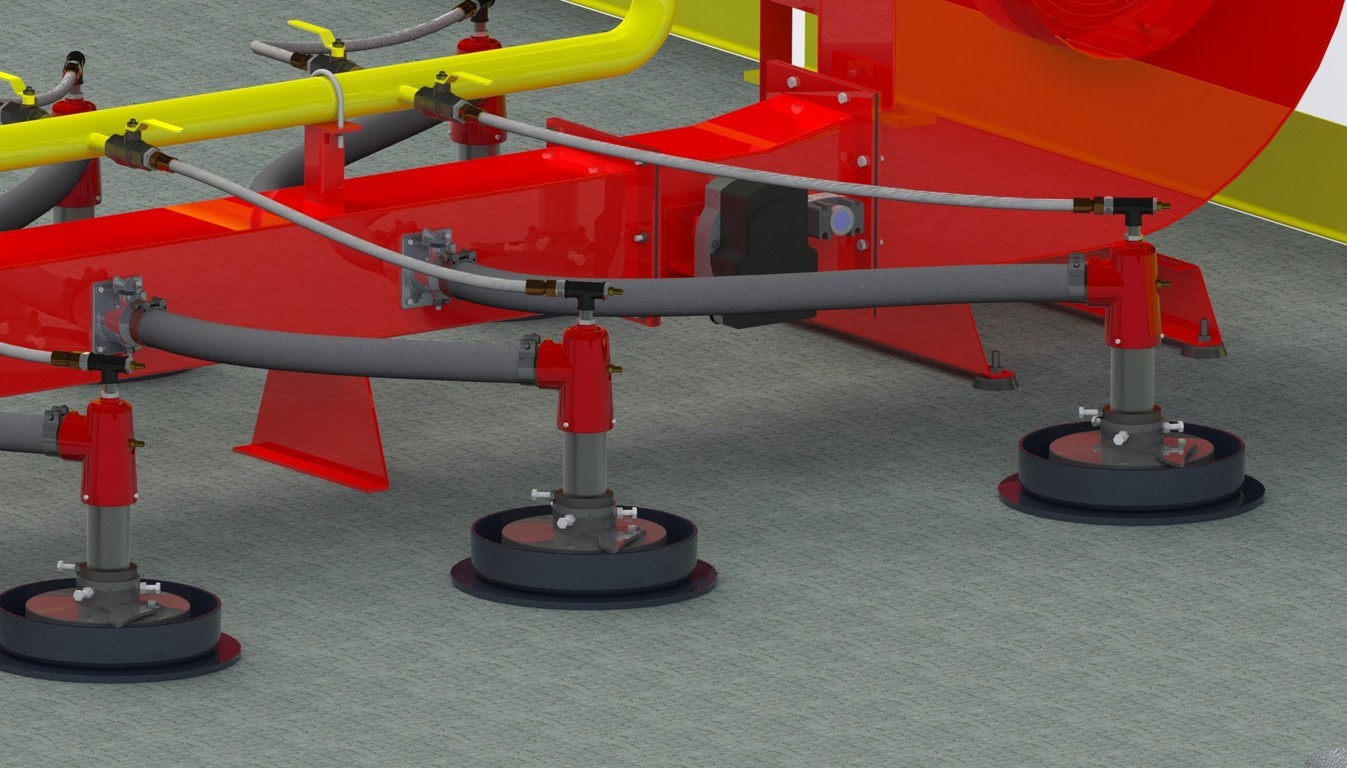

Gas feeding system SUPERTEC, composed by 10 up to 16 injectors are mounted on the flat kiln arch, in the kiln firing zone. They can be fuelled with natural gas Coal gas or LPG in the automatic mode and work with an air/gas mix adjusted for controlled combustion and even firing of the material throughout the pack. ALPINA TURBO GAS S feeder burners feature a gas distribution system, an air distribution system and mixing pipes. Gas, intimately mixed with a turbulent air current, is uniformly injected in the kiln and its combustion is instantaneous in firing zones where the temperature of the atmosphere is above fuel self-ignition temperature. Air inlet by means of a fan mounted on each group allows an ideal automatic regulation. ALPINA TURBO GAS S feeder burners groups can feed as many as 8 to 16 firing holes set in two firing rows; they are fitted with a safety valve that stops gas flow in case of electric current fault, insufficient minus-pressure inside the kiln, too high or too low gas pressure.

ALPINA TURBO GAS S feeder burners are made up of:

- High-head fan unit

- Air/gas powered valves for the automatic modulating regulation, with air presence safety pressure switch

- Security Gas manifold and distributor complete with cut-off valves and pressure gauge

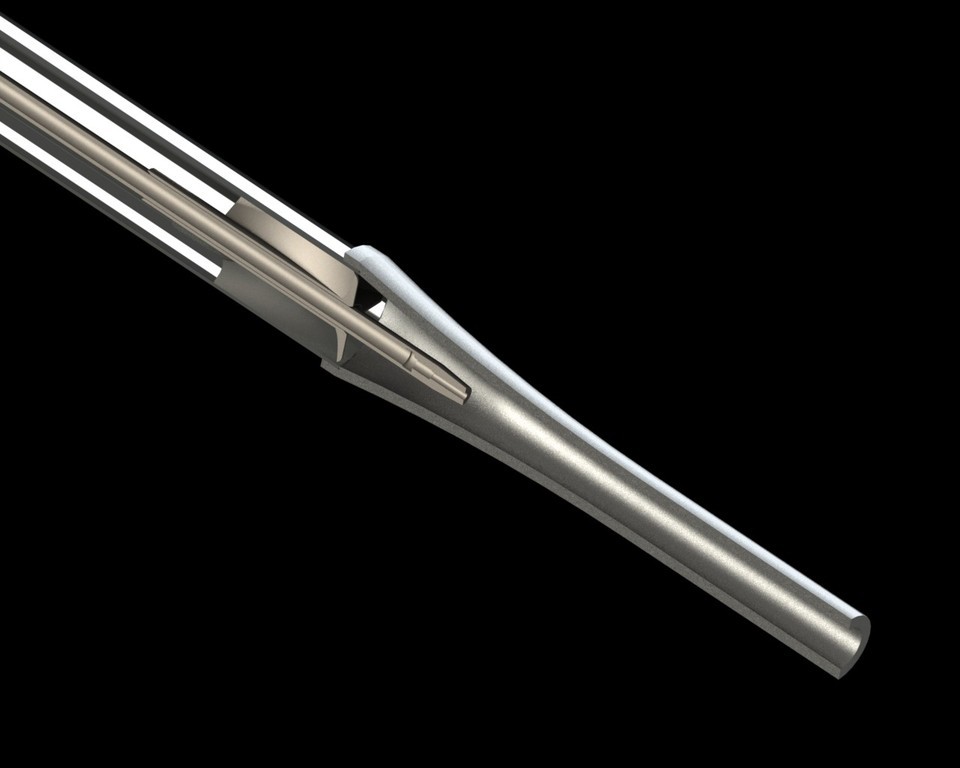

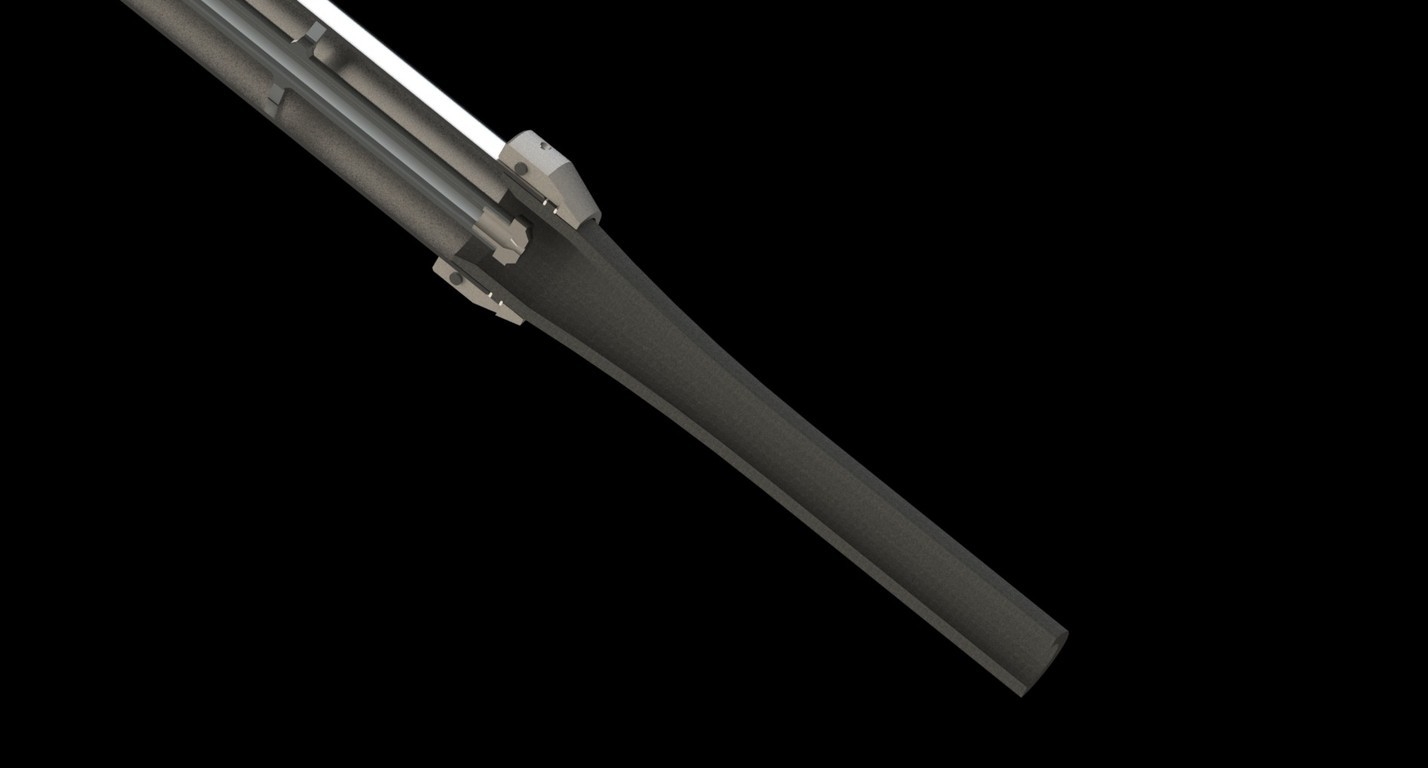

- AISI 310S Stainless steel air gas injectors with refractory casting steel head